|

自動超音波

オンライン用装置

|

|

| UT応用例 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UTオンラインシステム

On the occasion of this year's Tube & Wire fair in Dusseldorf, the company

KARL DEUTSCH Pruf- und Messgeratebau GmbH + Co KG (NDT Instruments & Systems) presents

the current state-of-the-art of automated ultrasonic inspection. Ultrasonic testing is

used for the reliable and nondestructive detection of material defects. For more than 35

years, KARL DEUTSCH has shipped automated inspection systems to customers world-wide. The

focus was always placed on applications found e.g. in steel mills.

For ultrasonic bar inspection the tendency towards 100%-coverage of the cross section is

observed while high inspection speeds are also mandatory. The various inspection concepts

depend on the surface condition, the straightness and the diameter of the material.

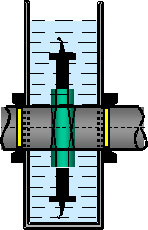

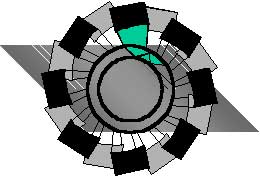

For highest demands with respect to safety-relevant components, the HRP-concept

(High-speed inspection of Round Profiles) is recommended. The ultrasonic probes are placed

around the bar material. The immersion technique is used (figure 1). An important feature

is also the possibility to inspect various profiles such as squares or flats with only

little effort to change over the testing mechanics.

Two main applications are encountered for tube inspection. The full-body testing of tubes

uses concepts which are rather similar to bar testing. The second area is the automated

weld inspection. The most common application are tubes with longitudinal or spiral welds.

During the fair on April 10th, customers will have the chance to visit KARL DEUTSCH in

Wuppertal which is only 30km from Dusseldorf. A guided tour and a technical programme with

presentations including bus transportation is organised for approx. 3 pm.

|

|

|

|

| The immersion technique (ultrasonic probes and test material

under water) is successfully implemented for the non-rotational inspection of long

profiles, |

possible angle-probe configuration for tube

inspection |

HRP-mechanics for bar inspection |